Thanks to the ever-growing attention to sustainability, recycling, ecology and natural authenticity, there has never been a better future for flax. Our flax fibres have already long found their way to especially innovative applications, like into the non-woven and composite material segment of the industry.

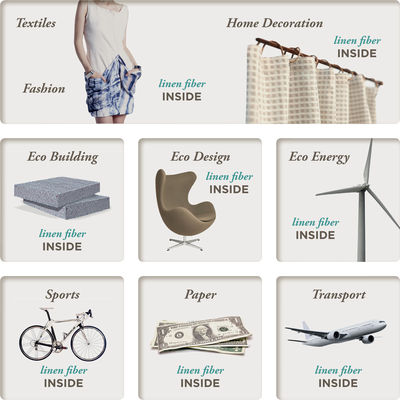

At Castellins, we are very proud to be able to contribute to this strong flax revival. Although our greatest market (approximately 70%) is still fashion/clothing and household linen, the remaining 30% in highly technological applications has been gradually gaining importance.

ECO DESIGN: flax as a resource in ultra-light composite material, such as for the automotive industry. Fibre plate is also made with it, for example, for the production of modern furniture.

ECO BUILDING: flax is also made into thermal or acoustic insulation material, for example for roof and car door insulation.

SPORTS: flax is also cropping up more and more in light composite materials used in the production of tennis rackets, surf boards and bikes, where its supple properties mainly serve to better absorb shocks and vibrations.

ENERGY: flax dust can serve as a source of energy by processing it into biogas.

PAPER: flax is used to strengthen paper, amongst other things in bank notes and cigarette paper (the latter also because of its natural taste).

LIFESTYLE: oil is pressed from linseed/flax seed and is used in cosmetics, paint, linoleum, cleaning products.

HEALTHCARE: flax can be encountered more and more in plasters and compresses. Also natural wound stitching thread is made of flax fibres and is already being used in many surgical spheres.